This post is co-authored by Ayman Shoukry, Specright’s Chief Technology Officer and Kevin Tran, Engineering Manager at Specright.

The world is experiencing a tectonic shift in how things are made, and most supply chains weren’t ready. We saw it in the thousands of empty shelves early on in the COVID-19 pandemic. We see it in the countless recalls and the FDA’s rally cries for better supply chain traceability. And we’re at an inflection point: companies need to reinvent their approach to supply chain management or spend hundreds of thousands of dollars on the consequences because band-aid “solutions” no longer work.

That’s why long-time packaging and manufacturing executive Matthew Wright founded Specright, the first purpose-built platform for specification management software.

Founded in 2016, Specright’s platform enables companies to digitize the specification data that typically lives in spreadsheets, PDFs, and legacy systems like Lotus Notes into a single, cloud-based platform. With all this data in one place, companies are able to better manage their products and packaging to accelerate product development, report on sustainability, and drive traceability across their supply chain network.

In this post, we show how Specright uses Amazon Quantum Ledger Database (Amazon QLDB) to create a traceable supply chain network called the Specright Network, which enables wholesale brands, retailers, and manufacturers to share critical supply chain data and packaging specifications data.

Why most companies don’t have the data they need to drive traceability

Companies in industries ranging from food to beauty, CPG, and heavy industry have spent a decade throwing people and processes at this problem without treating the root cause of supply chain traceability: poor specification data management.

When a product is made wrong because of incorrect information, brands shouldn’t immediately blame suppliers. They should first evaluate how they were managing the data to make that product to begin with. For most companies, this is easier said than done. Most are managing their specification data in spreadsheets, legacy systems, ERPs—or in email inboxes. In fact, many rely on their suppliers to manage the data needed to make their own product. And when a product changes (and they often do), it’s a game of telephone to communicate the latest version to suppliers, co-manufacturers, retailers, and even consumers.

The reality is this communication and chain of custody isn’t handled in a professional system, but a patchwork of processes that can result in product waste, quality issues, and spec drift, a phenomenon where products morph over time unbeknownst to the brand.

But luckily, technology is going through an upgrade cycle when it comes to managing specification data. We’ve gone from flip phones to smartphones. Maps to GPS. Technology is critical to helping us, as a society, move faster. Which is why the supply chain is going through one of the biggest upgrade cycles yet with the emergence of Specright, the first specification management software.

The shift from supply chains to supply networks

To further complicate things, we’ve graduated from supply chains and into supply networks. This means no more linear, consolidated supplier streams, but rather, flexible, networked supplier streams, in which quick pivoting and real-time response is required.

We live in an “everything now” world, where product moves fast. So companies are looking for ways to move faster and share data across companies. Which is why Specright launched Specright Network, powered by Amazon QLDB.

Companies are in desperate need of supply chain transparency and better ways to collaborate with one another. The Specright Network is taking collaboration to the next level. On the Specright Network, members can share and publish specification data from other pre-vetted members. This means no more emails or phone calls when specifications change. For example, a packaging supplier can publish and share a new specification to multiple customers on the Specright Network. After the specification goes through internal reviews, the user just needs to hit “publish”— it’s that easy.

With a fully secure, immutable, cryptographic system, the Specright Network just made data accuracy, visibility, speed to market, and supplier management easier.

“Specifications change constantly due to a variety of reasons. Regulatory compliance, sustainability efforts, and marketing initiatives are just a few of the drivers on that list. Ultimately, the entire supply chain is impacted,” said Jason Higbee, General Manager at Cal-Organic Farms, a division of Grimmway Farms, a global produce leader and the world’s largest producer of carrots. “Specright’s Network has the potential to improve visibility, organization, and change management of critical specification data across the supply chain while increasing efficiency and control.”

How Specright used Amazon QLDB to create the Specright Network

Ayman Shoukry, Specright’s Chief Technology Officer, and his team explored different technology partners for Specright Network. They ended up selecting Amazon QLDB as the key engine of the Specright Network due to the ease of use and architectural flexibility. Specs, as previously mentioned, are the DNA of how products are made. Having an immutable history of specification data and who on the network is changing specs is fully tracked via Amazon QLDB.

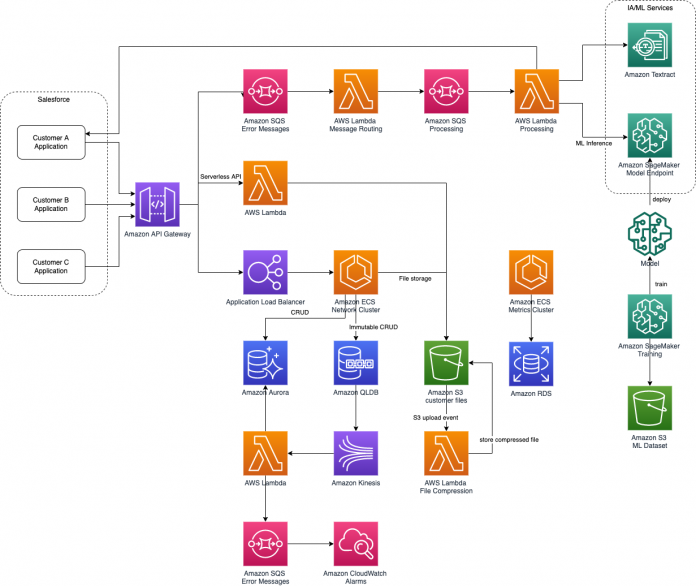

All specifications published to the network are first sent to Amazon API Gateway. For specifications with unstructured data, the company utilizes Intelligent Document Processing (IDP), which utilizes the latest industry-standard AI and machine learning (ML) techniques to enable clients to convert their documents quickly and easily into digital specifications that can be shared to the Specright Network.

In the architecture outlined in the following diagram, document upload events are sent to API Gateway and routed to an Amazon Simple Queue Service (Amazon SQS) queue via a direct integration. Amazon SQS allows Specright to control the flow of requests and to monitor any errors using dead-letter queues (DLQs). These upload events trigger serverless AWS Lambda functions that call Amazon Textract to extract data from these documents. The data is then sent to ML model endpoints hosted within Amazon SageMaker for real-time analysis. On completion of each analysis, Lambda delivers WebSocket notifications through API Gateway to notify registered clients. Clients can review the analysis results and provide feedback, which is stored in Amazon Simple Storage Service (Amazon S3). That feedback data is utilized in the training pipeline in SageMaker to improve the ML model’s accuracy and performance.

Specifications generated from the analysis are eligible to be shared to the Specright Network. When the specification is ready to be shared, it’s sent to the API Gateway, which forwards the requests through an application load balancer to services hosted on a scalable Amazon Elastic Container Service (Amazon ECS) cluster. These services are responsible for storing the data within Amazon QLDB and Amazon S3. Files uploaded to Amazon S3 also trigger a Lambda function to compress the file, which allows for more optimal storage usage. The data in Amazon QLDB is streamed to Amazon Kinesis by way of Amazon QLDB streams, with any failures being sent to a DLQ for later review. This action triggers a Lambda function to push data into an Amazon Aurora database for better indexing and faster read-only access.

The architecture makes sure that all members of the network have access to the same and latest version of the specification. This enables companies to squash spec drift and easily authenticate their products via Specright Network.

This level of transparency is key for managing and controlling complex supply chain networks. After all, a packaging change that’s not communicated can impact the supplier, brand, and retailer, which can result in recalls and or rejected shipments.

With Specright Network, companies can avoid the bullwhip effects of supply chain changes and instantly track change history to investigate quality issues. Workflows that used to take weeks and months are now feasible in days or hours.

One thing is certain: supply chains aren’t slowing down. But with Specright Network, brands, suppliers, and retailers can finally keep up.

Conclusion

In this post, we showed how Specright uses Amazon QLDB to help companies manage all the data they need to make things—ingredients, formulas, bills of materials, products, and packaging—and easily share data with partners across their supply chain network.

If you want to learn more about Specright, we encourage you to visit the Specright website and explore their product specification case studies.

For hands-on experience with Amazon QLDB, you can reference the Amazon QLDB workshops and explore the Developer Guide.

About the Authors

Ayman Shoukry is the CTO of Specright, the first purpose-built platform for Specification Data Management. Ayman started his career with the Microsoft Developer Division product groups where he spent over 15 years. He then joined HireRight (a world leader in the background screening market) where he was the company’s CTO and part of the executive team who drove the company’s successful exit and its acquisition by a major private equity. Just before joining Specright, Ayman spent some time in Amazon as part of the core e-commerce platform team. Ayman brings executive level experience that focuses on strategy setting and team growth.

Kevin Tran is the Engineering Manager at Specright. He has over 12 years of experience in engineering, modular and object-oriented programming, specializing in enterprise applications. He is deeply experienced in cloud native architectures and has a proven track record in delivering robust applications to improve business operations and profitability.

Charles Okochu is the Global Business Development Manager for Amazon Managed Blockchain and Amazon Quantum Ledger Database (QLDB). He is based out of New York City and has a background in Financial Services, Blockchain, Digital Assets and is passionate about how blockchain technologies can transform the technology landscape. In his spare time, Charles enjoys running, playing and coaching soccer, and spending time with friends and family.

Read MoreAWS Database Blog